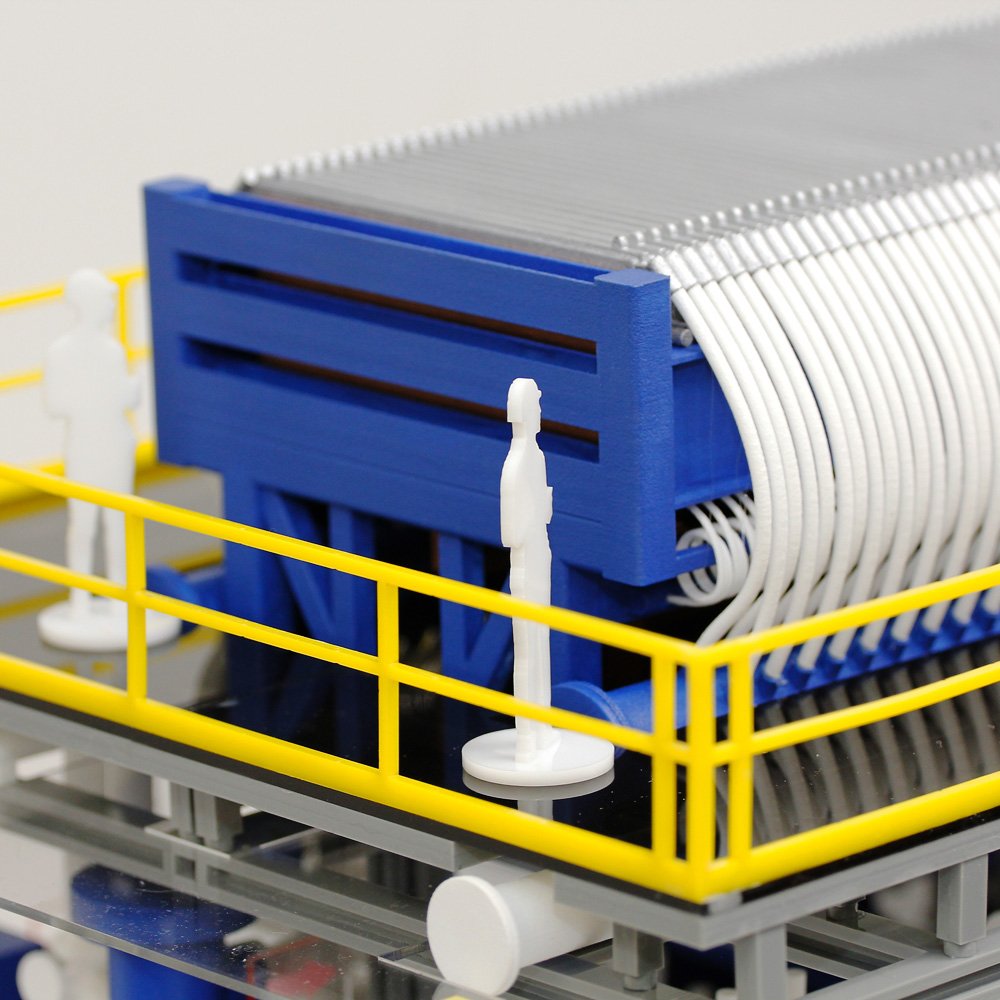

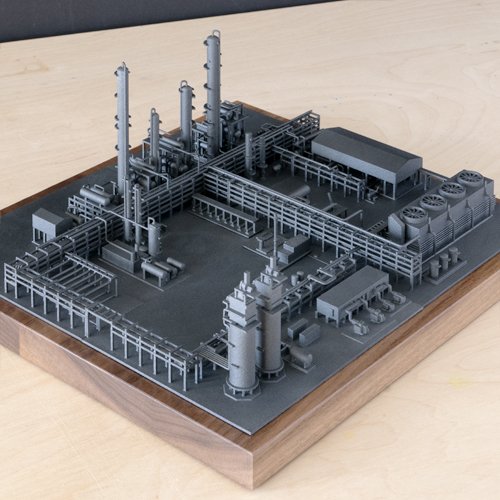

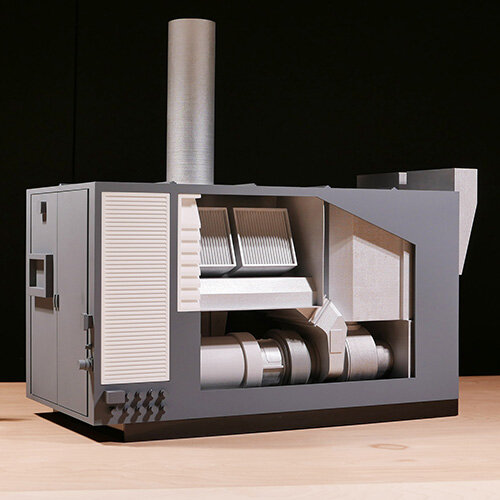

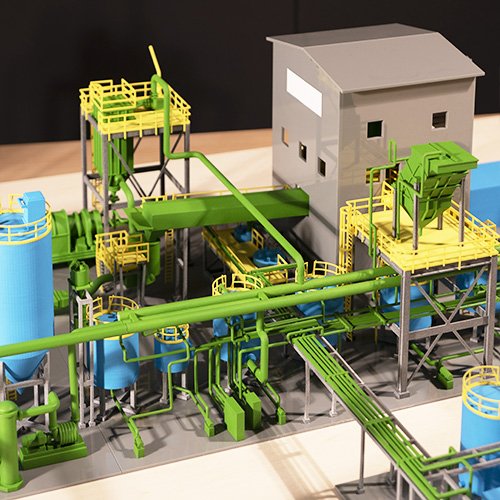

Transform Your Projects into Eye-Catching Models with our Expert Model Making and 3D Printing Services

Model Maker Studio offers a comprehensive range of state-of-the-art services that bring your projects to life in stunning detail. Whether you need models for trade shows, marketing campaigns, engineering and medical prototypes, or promotional giveaways, we have the expertise and technology to turn your vision into reality. With a focus on quality, craftsmanship, and innovation, we are dedicated to exceeding your expectations and delivering exceptional attention-grabbing models every time.

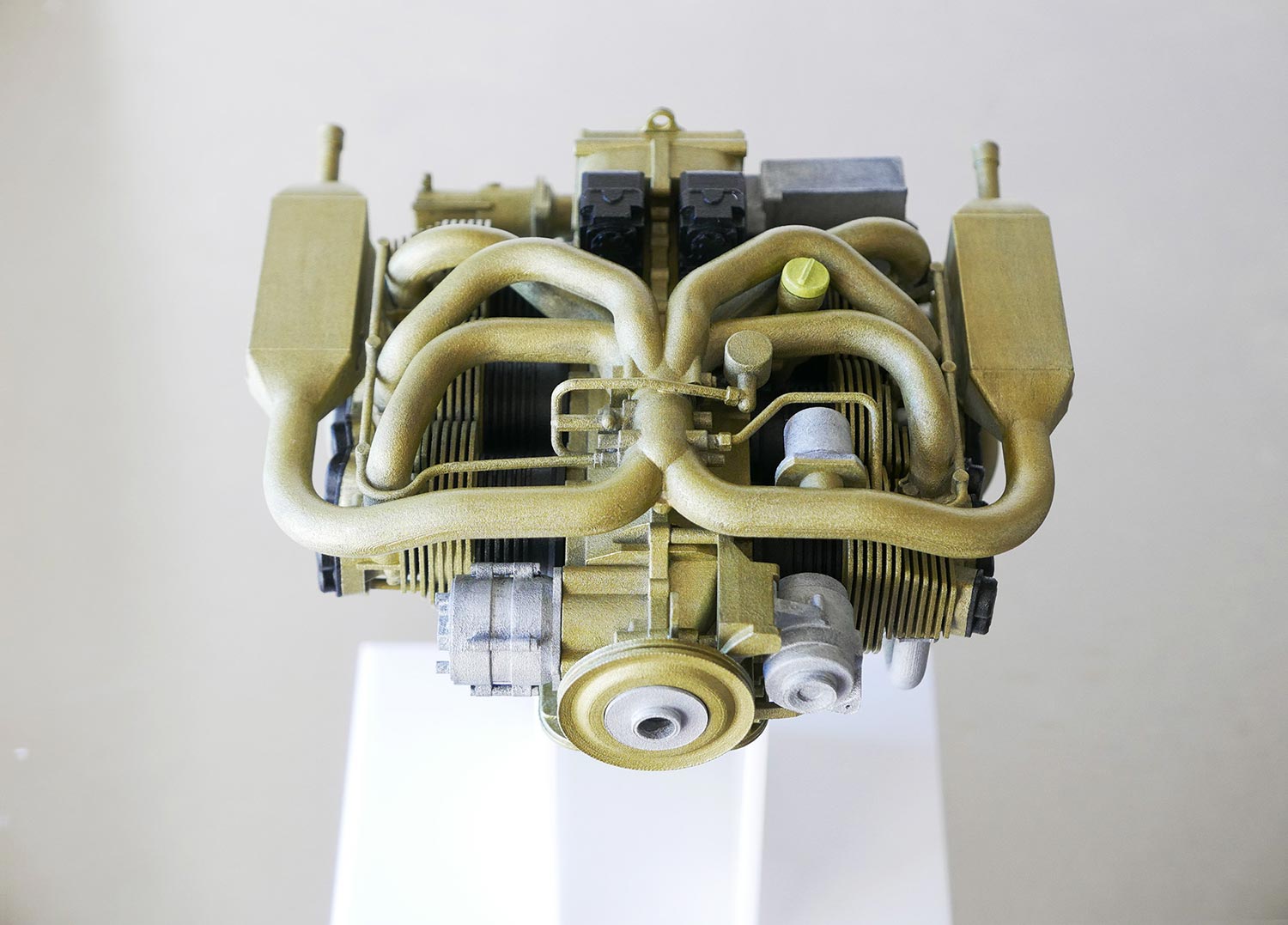

-FlexEnergy

"The model is beautiful! It looks even better than I imagined. You’ve done a fantastic job. Thank you so much for all of your great work and care in creating and packaging the piece. We’re excited to showcase it at an energy show in Oman. I look forward to working with you again when our other design is finalized."

-GCON

"The model was a huge success at the Interphex biopharmaceutical trade show and drew a lot of attention to our booth. The model is a success everywhere we take it"

-ESA Renewables

“Wow! The model looks amazing! I am so excited to show our team. Thank you very much for all your hard work. I will definitely let you know about future projects”

-Locix

“I set up the model at the office and it looks fabulous. We’re super excited to show it off here and at trade shows! Couldn’t be happier with the result.”

-Midé Technology Corporation

“I have recommended you to my fellow coworkers and will try to ensure that Midé uses you in the future. Thank you very much for all your help,”

Apple

Autodesk

Bank of America

Foster & Partners

GEA

Gensler

Google

GSI

Herrero Boldt

JPL

NASA

Nike

Northwest Airlines

NCL

Optimized Process Designs LLC

Oracle

Pixar

Pfizer

Raytheon

SFMOMA

Smith Group

SOM

Stellar

SWA Group

Targa Resources

Tesla Motors

TE

Toyota

U.S. Navy

U.S. Air Force

Verizon

Veterans Administration

Yale University